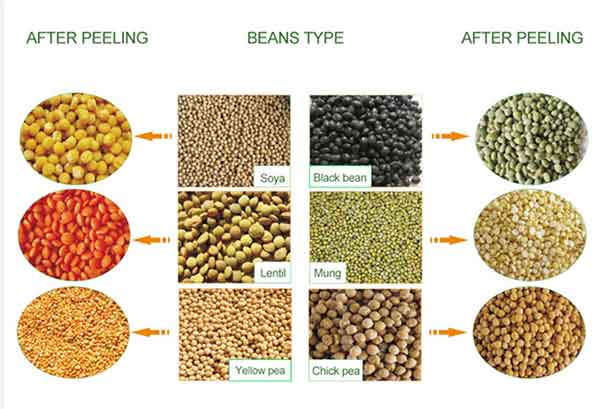

MTPS Bean peeling machine can be used as the supporting equipment in bean processing technology or as the single equipment. It can process lentil, peas, mung bean, chickpea, lupin beans, soybean and other similar sizes of beans.

Win Ton's MTPS Bean Peeling Machine can be divided into different models according to different characteristics of pulses, which includes MTPS-18A, MTPA-18B, MTPS-18S, MTPS-25B, MTPS-25B and other series products. This kind of bean peeling machine can be used as the supporting equipment in bean processing technology or as the single equipment. It can process lentil, peas, mung bean, chickpea, lupin beans, soybean and other similar sizes of beans.

The machine is used in the peeling process for bean processing and primary and further peeling process for food processing enterprises. It can be used in series or in parallel in complete processing line according to technological demand. Bean peeling machine can process red bean, kidney bean, soybean, mung bean, lentil ; it is suitable for different beans peeling when changed related technical parameter.

MTPS bean peeling machine is mainly composed of fittings of base frame, main shaft, charging regulation device, charging hopper, channel, air blower parts, cyclone parts, protective cover, propelling chamber, instrument, pressure door, guide cylinder, upper and lower beams, motor base, sieve plate, bearing base, motor, belt.

The material is conveyed by the screw propeller to the peeling chamber which is at the machine’s core part. It utilizes the emery with high speed rotation and cuts and rubs the beans skin continuously, which destroys the bonding strength among bean bran, material skin and endosperm, and makes bean bran separated gradually. Then the material is conveyed to the outlet of the equipment and the peeling process is finished.

Its built-in suction and dust removal system ensures the best sanitary conditions.

MTPS bean fine peeling machine connects with the efficient aspiration system, which ensures reliable discharging of bean bran. It has the powerful cooling system and ensures the high sanitation standard.

It is easily maintained and operated.

It has quick-replaceable sieve plate and other parts. The durable emery roller and less abrasion parts make the equipment easily operated and maintained.

| Model | Emery Roll Diameter (mm) | Emery Roll Length (mm) | Spindle Speed (r/min) | Yield (t/h) | Power (kW) | Air Volume (m³/h) | Size (L*W*H) (mm) |

| MTPS-18D/A | Φ180 | 660 | 1300 | 1~1.5 | 22 | 1370×700×1900 | |

| MTPS-18D/B | Φ180 | 660 | 1300 | 1~1.5 | 22 | 1500-1800 | 1410×1220×2030 |

| MTPS-25D/A | Φ240 | 660 | 1050 | 2-3 | 30 | 1515×660×2100 | |

| MTPS-25D/B | Φ240 | 660 | 1050 | 2-3 | 30 | 1800-2100 | 1515×1220×2100 |

Workshop Processing for Bean Peeling Machine:

Shown at Exhibition Hall:

Peeled Beans:

Peeled Lentil:

Peeled Mung Bean:

Peeled Chickpea:

Peeled Peas:

Peeled Soybean:

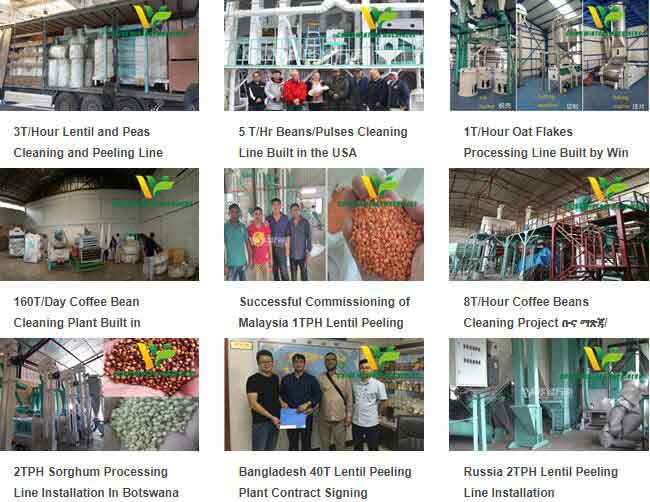

Application Overseas (Part) :

Canada 120T/Day Lentil Peeling Project:

24T/Day Mung Bean Peeling Line in Thailand:

2T/Hour Lentil Peeling Line in Russia:

2T/Hour Lentil Peeling Line in Kazakhstan:

1T/Hour Lentil Peeling Line in Ethiopia:

2T/Hour Lentil Peeling Line in Ethiopia:

1T/Hour Lentil peeling line built in Malaysia:

More Cases:

VIDEO:

Please feel free to give your inquiry in the form below, We will reply you in 24 hours.

Scan visit mobile website