Based on the structural characteristics of quinoa, China Win Tone Company has developed quinoa peeling machine and quinoa polishing machine and also applied it to the dry quinoa processing production line to improve the traditional processing technology with washing and wet method. This technical project has been used in Yunnan province in China, and also put into use in many countries and regions including foreign countries like Bolivia, Peru and Argentia.

The whole quinoa processing plant needs 6 steps, here are the main equipment in the quinoa processing:

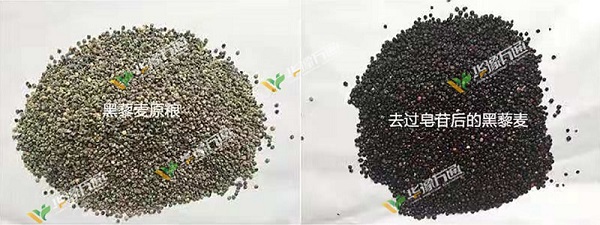

The complete set of dry quinoa processing equipment can be divided into multiple processes such as raw grain cleaning, stone removal, hull removal, saponins removal, quinoa polishing, quinoa grading, and color selection. The all-dry processing technology used is better than wet processing to maintain the quinoa flavor and reduce nutrient loss. In addition, our company has improved the equipment for the cleaning section of quinoa raw grains to select shriveled seeds to improve product quality.

Our company introduces all-dry quinoa processing technology. Not only can it effectively preserve the value of Lei wheat than wet processing, reduce water consumption and drying links, but also protect the environment and improve product market competitiveness.

In response to the complex impurities of quinoa, the cleaning process was strengthened, and specific gravity screening equipment was introduced to remove the shriveled seeds and improve product quality.

The application of the sand roller quinoa peeling machine and quinoa polishing machine developed by China Win Tone Company in the quinoa processing technology of quinoa not only improves the yield of the finished product, but also improves the quality of the quinoa. The surface of the processed quinoa is clean to reduce the loss of the original flavor of quinoa.

Combined with corn, millet, rice and other processing technologies, our company introducing dust removal and automatic control systems to accurately control quality to make sure processing workshop dry, clean and dust-free, and design the quinoa processing plant as a work of art.

Please feel free to give your inquiry in the form below, We will reply you in 24 hours.

Scan visit mobile website