1. Used in semidry method and dry method corn processing plants as the separating equipment for corn germ and corn albumen so as to improve corn products quality and the value of corn processing auxiliary products.

2. It is the core equipment in corn germ extraction for alcohol enterprises, starch enterprises, starch sugar enterprises and feeds enterprises.

TTPD Series of Corn Rubbing Degerminator

Corn rubbing degerminator usage:

1. Used in semidry method and dry method corn processing plants as the separating equipment for corn germ and corn albumen so as to improve corn products quality and the value of corn processing auxiliary products.

2. It is the core equipment in corn germ extraction for alcohol enterprises, starch enterprises, starch sugar enterprises and feeds enterprises.

Corn rubbing degerminator can rigidly strike and softly rub corns into 6-8 squares and uniform pieces, ensuring integrity of germs; TTPD Corn rubbing degerminator is an ideal equipment for corn fine& deep processing companies, liquor, oil, starch, starch sugar and feed plants.

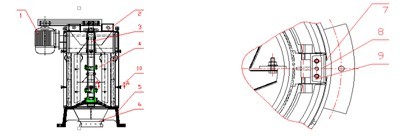

Main Components of corn rubbing degerminator:

1. motor 2. charge-in hopper 3. conveying device 4. rotor 5. bracket 6. discharging hopper

7. toothed plate 8. rubbing plate 9. angle plate of the rotor 10. pressing handle wheel

Corns flow from the glass cylinder and go in the space between rotor and toothed plate group. Motor drives the rotor spindle to rotate. Corns are rubbed and struck to be hulled between rubbing plate and toothed plate and go out through discharge hopper of corn rubbing degerminator.

Corn rubbing degerminator working principle and features:

Win Tone TTPD series of corn rubbing degerminator is the core equipment in corn germ extraction processing line project. TTPD series of corn rubbing degerminator has two models: TTPD50X72 and TTPD75x100. which can process 3 tons of corn and 6 tons of corn per hour respectively.

Corn rubbing degerminator uses cutting and centrifugal strike between rotor and toothed plate to work. Under the comprehensive effect by crash and friction among corn kernels, it breaks the corn albumen structure, the combination strength of the corn germ and the combination strength between the corn albumen and the germs to realize corn peeling, corn degermination and corn grits smashing.

It can effectively separate the corn germs, husk and albumen according to corn structure and reduce miscellaneous material and albumen loss so as to get high purity and whole kernel rate of end products.

By adjusting the interval between the rubbing plate and the toothed plate, it can degerm the corn with different moisture and density and has high degermination rate.

It adopts dry method degermination with low fat content and reduces energy consumption and equipment cost.

It doesn’t need grain moisturing or water in dry method degermination. Compared with wet method, it is much more sanitary.

It doesn’t need steam for tempering in advance so as to save lots of cost.

Please feel free to give your inquiry in the form below, We will reply you in 24 hours.

Scan visit mobile website